Silica Gel: Earth Pearls, Purifying Life

Sinchem Silica Gel Co., Ltd., SINCHEM was established in 1993 as a company specializing in the production of synthetic amorphous silica.

The products are Sodium silicate, silica gel desiccants, silica gel cat litter and a lot of silica gel for industrial use.

SINCHEM employees more than 800 people around the world.

New office in Strasbourg, France

OUR VALUES

Synthetic amorphous silica is produced from silica sand, which is composed primarily of silicon dioxide.

With its exceptional chemical stability, the synthetic amorphous silica is used in a wide range of commercial applications and has become indispensable for today’s modern way of life. SINCHEM is continuously exploring silica’s dynamics to develop new applications of this versatile material. Similarly, we are guided by evolving technology to uncover greater possibilities toward meeting the needs of a diverse marketplace. SINCHEM extracts and produces more than 900 tons per day of Silica gel and sodium silicate.

MODERNITY

SINCHEM is present now in China and Europe: in China, in the Shandong province close to the mines and to Qingdao, Shanghai and Tianjin ports and in Europe in Strasbourg, France – the capital of Europe and an important port. These are two major offices providing the group with two important geographical anchor-points.

SINCHEM persistently upgrades its installations: in 2016 with a new warehouse of 6000 sq. meters and a new plant with an increase in capacity of 35% is planned for the second semester of 2017.

Products are used in cat litter, paint, adsorption separation purification, silicon rubber and tire filler, desiccant, indicators, pharmaceutical personal care (cosmetics, toothpaste, and pharmaceutical silica) and catalysts. More than 25% of our products sold today did not exist 3 years ago.

NATURAL

Silicon is the second most important element in our planet after oxygen.

Our installations are located close to the mines, allowing a significant reduction in transport costs. Extraction is facilitated by the fact that quartz is at ground level. We transform the stones into quartz sand with very high purity.

We use process water in a closed loop during 24 hours. In order to get high purity silica gel, water reverse osmosis treatment is applied. The working principle is to give certain pressure on the water. The water molecules and ionic minerals can penetrate the osmosis membrane, while the inorganic salts (heavy metals), organic matter, bacteria and viruses that are dissolved in water cannot, so that pure water and the other matters can be separated. After the pre-treatment and reverse osmosis treatment, the conductive medium in water can be removed completely. Generally, the water resistance can reach 8000 Ohm. This technology can guarantee that a high washing medium is provided to wash silica gel. Responsible usage of this resource reduces amounts of waste water.

Silica production system requires a great quantity of energy. The primary responsibility of power plant is to provide sufficient steam pressure and heat to dry silica products so that we can provide customers goods with stable quality and controllable water content. The power plant can also serve other electric equipment. SINCHEM power plant is designed, operated and maintained strictly in line with National Electrical Operation Specification. We apply an environmentally friendly and highly-efficient 75T/H circulating fluidized bed (CFB) boiler to achieve sustainable development and have a green chemical industry.

SINCHEM has all the certificates that allow the sale of our natural products in Europe, ISO 9001:2008, ISO 14001:2004, REACH registration, Global Standard for Consumer Products, SGS-ROHS, membership of APPA, Green Enterprise Chinese Label and adherent to Business Social Compliance Initiative (BSCI).

QUALITY

The SINCHEM Technology Center is equipped with TriStar II3020, manufactured by American Micromeritics Instrument Corp., which is a fully automated porosity analyzer. It can be used to conduct isothermal adsorption and desorption test, and to test the specific surface area, micro pore volume and area distributions, mesoporous pore volume and area distributions, total pore volume, etc. Three silica gel samples can be analyzed simultaneously to improve efficiency. The analyzer can provide a full adsorption curve, desorption curve, BET and Langmuir specific surface area, average pore size and total pore volume in 1Pa, BJH mesoporous value, large pore volume, size distribution and total pore volume.

Forty-five engineers in Chemistry, Mine exploitation, Industrial Process, Quality control, Machinery, Electronics, Electricity and Environmental protection guarantee evolving knowledge and talent. SINCHEM has established long-term agreements with external suppliers.

SINCHEM proposes a complex business requiring heavy and ongoing investment in its employees, chemical processes, technologies and production tools. Training, innovation and a full understanding of the market served are crucial factors of success.

SINCHEM periodically measures the quality of air, water and waste in order to reduce aqueous and atmospheric rejections constantly.

SECTORS

01 INDUSTRY

Silica gel can be used in decontamination, separation and purification of gas, its application can be widely found in synthetic ammonia industry, pressure swing adsorption (PSA) and many other fields.

PSA is an advanced technology in gas separation and purification, PSA silica gel is mainly used in the recycle, separation and purification of carbon dioxide gas. It is applied to the preparation of carbon dioxide in synthetic industry, food and beverage processing industry.

It can also be used in desiccation, damp-proofing and dehydration and refining of organic products.

02 BIOCHEMISTRY

Chromatography silica gel is a high-class selective adsorption material composed by aggregation-structured (structured-aggregation)colloid particles. Colloid particle is the polycondensate of hydrated silica gel, it is an amorphous substance. The gap between colloid particles forms the micropore structure inside silica gel granules. Therefore, Chromatography silica gel is a superior absorbent material with micropore structure, high specific surface area, high purity and high activity.

Chromatography silica gel is widely used in the separation and purification of effective components in Chinese herbs, preparation of high purity materials, dehydration and refining of organic products and brewing industry.

03 AGRICULTURE

Silica gel fertilizer can enhance disease resistance of rice, and improve its setting percentage, stimulate the growth and increase the yield.

It also can be benefit to crops’ photosynthesis and increase chlorophyll content, make the stem and leaf straight and upright, promote the accumulation of organic matter.

Silica gel fertilizer can strengthen the mechanical strength of crops’ stems; enlarge the lodging-resistance capability by more than 85 percent to make stems straight and strong, so it is good for compact planting.

It can improve the crops’ resistance to plant diseases and insect pests, to reduce various kinds of plant diseases and insect pests.

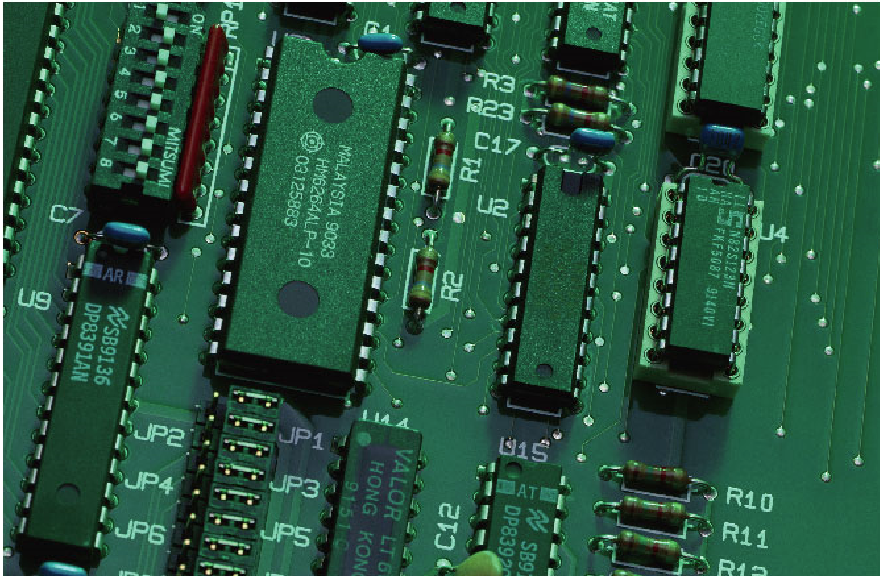

04 ELECTRONICS

Silica gel desiccant can protect semiconductor, circuit board and all kinds of photoelectric elements from moisture, static and corrosion during the storage.

05 HOUSING

Nano-photo-catalyst loaded on inner surface of the micro-pores.

Adsorption of formaldehyde, benzene series, ammonia, radon and some other harmful gas along with floating bacteria in the air.

Air humidity adjustment, odor control, mold proof, and sterilization in hotels and hostels, offices, living rooms, bathrooms, kitchens, ashtrays, cars, shoes and refrigerator

06 CAT LITTER