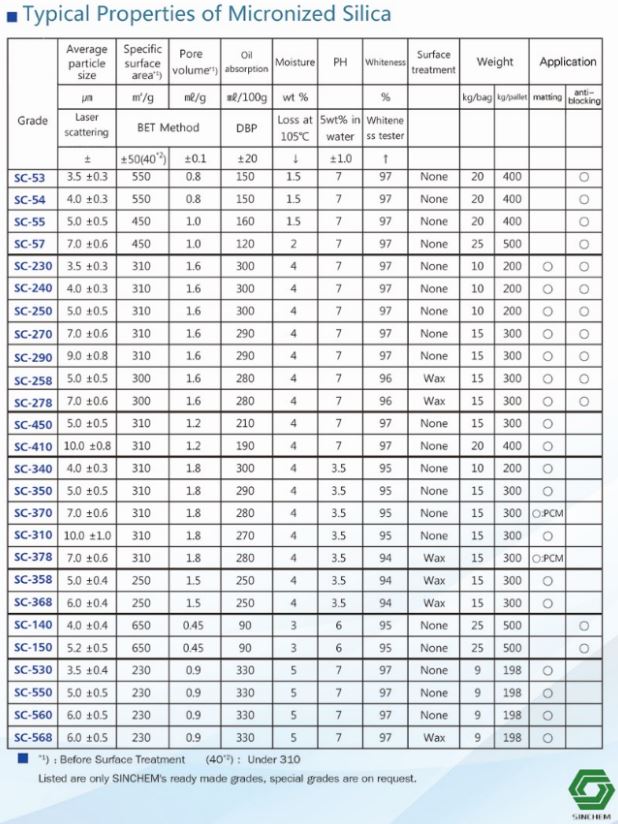

- Micronized silica is synthetic, amorphous, porous and acidic-base silica powder whose size ranges from 2 microns up to 20 microns.

- Micronized silica products offer the formulator an excellent balance and value of properties to meet demanding performance requirements.

- Micronized silica products are manufactured to exacting consistency, purity and quality standards.

- Pore Volume : 0.4 – 2.5 cc/g

- Surface Area : 200 – 800 m2/g

- Oil Absorption : 90 – 400 cc/100g

- Surface treatment : organic, inorganic

- Advantages of micronized silica in plastic

- Excellent dispersibility.

- Reproducible product quality.

- Stopping the blocking effect of polymer film.

- A nice finish to film, sheet and extrudes.

- Giving molds the release they need.

- The properties of Micronized Silica as an anti-blocking agent are maintaining transparency with the same refractive index of film and not being condensed between silica in film.

- Selecting anti-blocking agent for plastic film is very important because it has great effect on manufacturing condition and quality level of the film.