- The PSA can absorb certain gas more easily than other gases, so the gas easily adsorbed can stay in the PSA silica gel and be separated from others gases. In order to recycle the PSA, the gas having been adsorbed must be desorbed. One way of desorption is to make the air pressure in absorber lower than the pressure when the gas is absorbed. As the air pressure in absorber changes cyclically, it is called PSA.

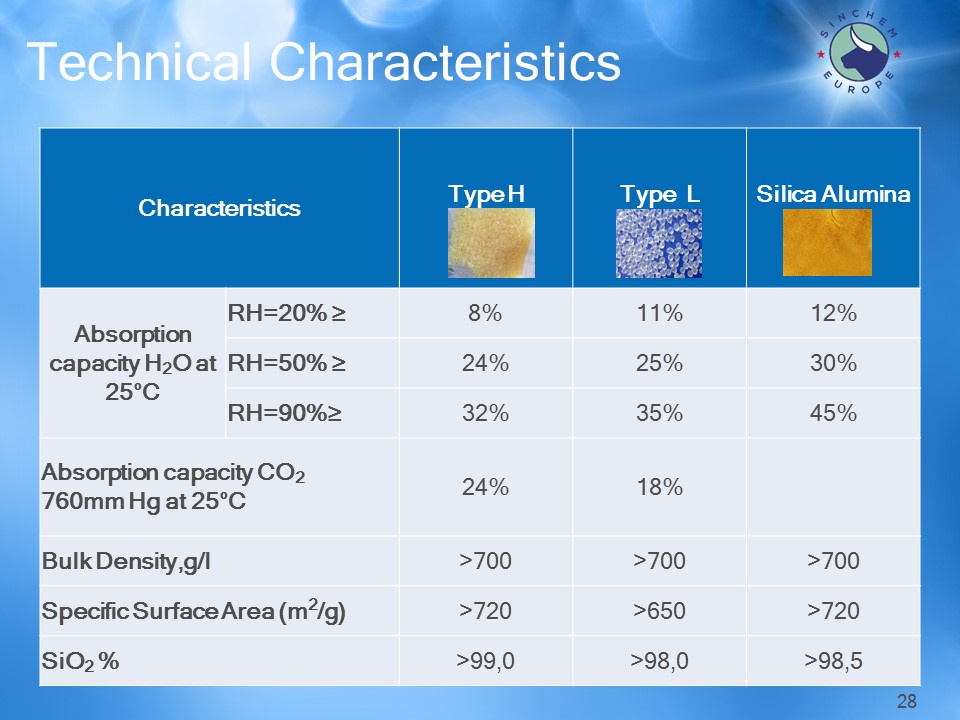

- The PSA silica gel has higher specific surface area and average pore diameter than regular Type A silica gel.

- Specific surface area must be above 780m2/g.

- Average pore diameter above 2nm.

- Higher ability in absorption equilibrium in low relative humidity.

- Two Types: Type H and Type L

- Silica Alumina Gel is used as PSA in very high relative humidity.

- Rigid structure

- High mechanical strength.

- No heat

- Used as catalyst and catalyst carrier in petroleum chemical field, dryer machine, liquid absorber, gas separating in industrial field CO2 and H2, and in the fabrication of NH3 and Urea.